From Wooden Blocks to Carbon Ceramics: A Brief History of Brakes in Cars

Brakes. They're not as glamorous as horsepower, wings, or tyre compounds, but let’s face it—without them, your track day becomes a demolition derby.

Today’s high-performance race cars benefit from some of the most advanced braking systems ever built. But where did it all start?

The Wooden Beginnings

The first “brakes” were literally just wooden blocks pressed against the wheels. In the late 1800s, with motorised carriages slowly replacing horses, early engineers stuck with what they knew—brake shoes borrowed from carts and wagons. They were primitive, noisy, and about as effective as dragging your foot out the door.

It worked… until cars got faster.

Enter Drum Brakes: A Revolution in the Roaring '20s

By the 1920s, speeds had increased dramatically—and the wooden block had met its match. That’s when drum brakes emerged, enclosing the braking mechanism inside a metal drum. This design allowed for better stopping power and protection from the elements.

But drum brakes weren’t without flaws. They were heavy, they heated up quickly under stress, and they faded like a cheap vinyl wrap on a Queensland summer’s day. Still, they dominated road cars for decades and remain in use on rear axles of some budget models today.

Disc Brakes Change the Game

Enter the disc brake—first seen on a production car in the 1950s (Jaguar C-Type, we’re looking at you). These marvels offered better cooling, less fade, and way more bite under pressure. Racers were quick to adopt the new technology, and before long, discs became the new gold standard.

Modern disc brakes evolved rapidly in both size and performance. Early units were around 200mm diameter. Today, high-performance cars regularly sport 350mm+ rotors, with some track cars and high-end road cars over 400mm! That’s family-sized pizza stopping power.

For material, the primary manufacturing method was and remains cast iron.

The Evolution of the Cast Iron Racing Brake Disc

Cast iron brake discs have been the backbone of racing braking systems for decades, prized for their durability, heat-handling, and consistent performance. But like every component on a race car, they’ve evolved significantly from their early forms.

In the early days of motorsport, solid one-piece cast iron rotors were the norm. While effective, they were heavy, prone to warping under extreme heat, and didn’t allow for much movement or expansion. As racing demands grew—along with speeds and temperatures—brake engineers sought better ways to manage thermal load and reduce unsprung weight.

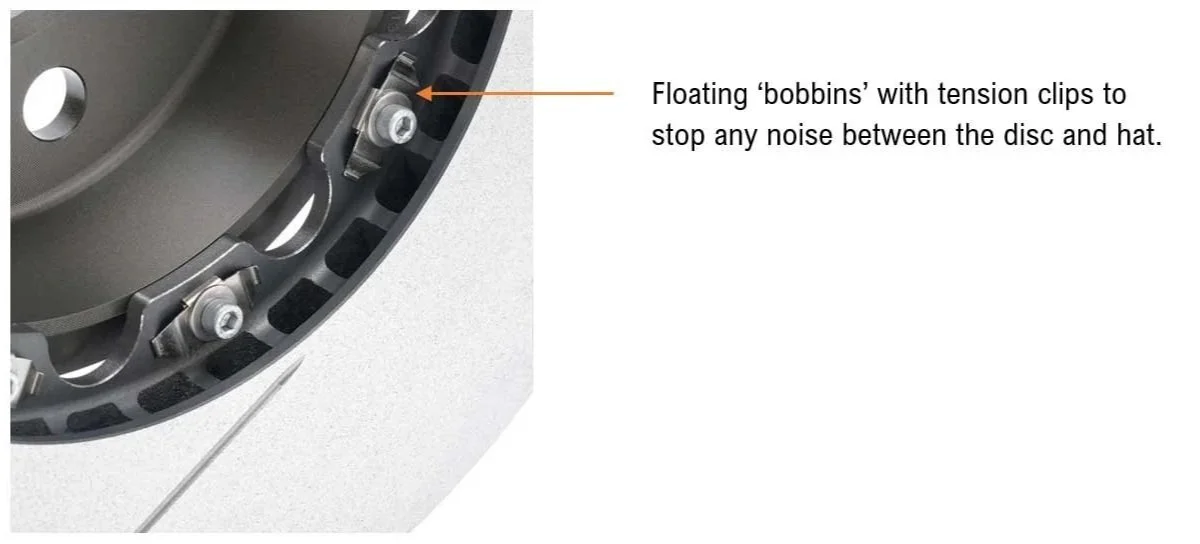

Enter the vented disc, which introduced internal vanes to improve cooling and increase structural stability. But the real game-changer came with the two-piece floating rotor. In this setup, the cast iron disc (or "friction ring") is bolted to a lightweight aluminium hat (or "bell") using a floating mechanism.

The ‘fully floating’ disc allows the iron ring to do two things:

1. Expand radially (or “grow”) when heated, reducing stress and helping prevent cracking or coning.

2. Move laterally to allow for movement in the suspension / caliper interface. This helps prevent the pads being pushed back in the caliper which can lead to knock-off.

So this floating dunction is designed to improve performance and reliability.

Today, two-piece floating cast iron rotors remain the go-to for many race cars—from club-level track builds to GT and touring categories—delivering the perfect balance of cost performance, and heat resilience.

Size Matters – But So Does Weight

Here’s where things get interesting for racers. Bigger rotors mean more stopping force, but they also mean more unsprung weight. That’s more weight for the suspension to deal with —and it directly affects your car’s responsiveness and grip.

That’s why motorsport engineers started experimenting with lighter materials.

Cast iron: durable and cheap, but heavy.

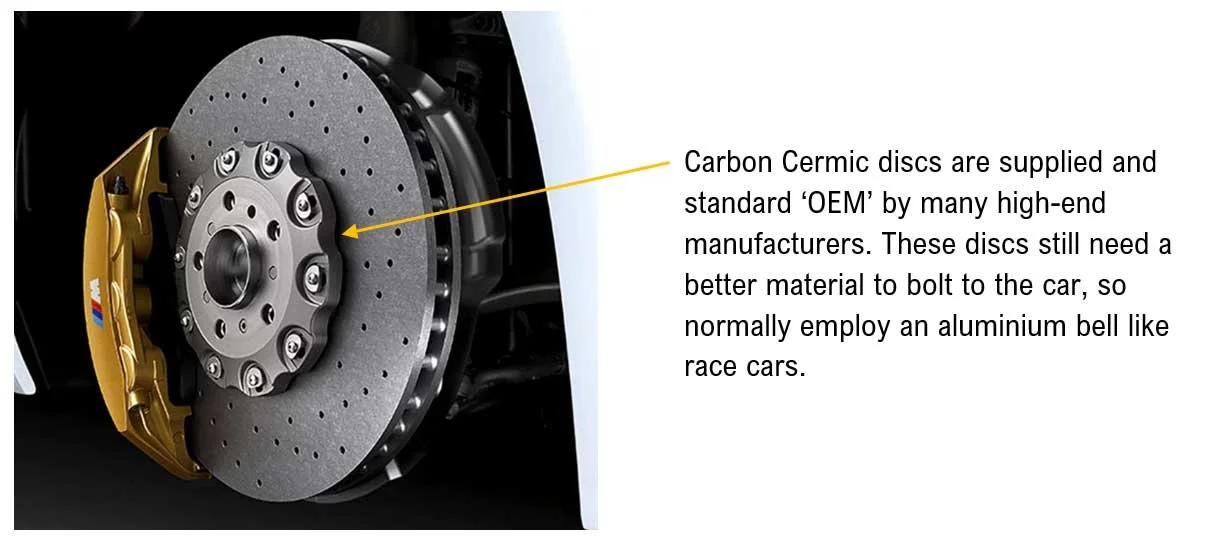

Carbon-ceramic: featherlight and fade-resistant, but eye-wateringly expensive.

Carbon-carbon: the holy grail in Formula 1 and top-tier endurance racing, offering insane temperature tolerance and weight savings.

Braking systems today aren’t just about brute force—they're finely tuned tools of control, made from exotic materials and often paired with clever cooling ducts, floating rotors, and high-performance brake fluids.

The Evolution of Racing Brake Pads: From Asbestos to Advanced Compounds

Racing brake pads have come a long way since the early days of motorsport, where reliability and stopping power were often secondary to just getting around the track. What started as simple friction materials has evolved into a science of high-performance compounds designed to handle extreme temperatures, pressures, and speeds.

In the early 20th century, brake pads were made using organic materials, including asbestos. While asbestos offered good initial friction and heat resistance, it came with serious health risks—and was eventually phased out. Organic pads also lacked the thermal stability required for high-speed braking, especially under racing conditions.

By the 1960s and 70s, semi-metallic brake pads entered the scene. These combined metals like copper or steel with organic binders, improving durability and heat tolerance. They were a big leap forward for race teams needing more consistent performance during long stints or aggressive driving. However, they were often noisy, abrasive, and still prone to fade under prolonged heat.

Then came carbon-metallic and carbon-ceramic compounds—ultra-high-performance materials built for professional motorsport. These pads could operate at temperatures well over 600°C without fading, offering razor-sharp bite and minimal performance drop-off lap after lap. The trade-off? They require proper warm-up and can be too aggressive (or expensive) for everyday or grassroots racing use.

Modern racing pads, like those from CIRCO, Winmax, Endless and others, use advanced non-asbestos organic (NAO) and hybrid metallic-carbon blends, tailored to specific racing formats—whether that’s sprint, endurance, rally, or track days. These compounds balance cold bite, high thermal tolerance, modulation, and rotor wear, giving drivers more confidence and consistency on the brakes.

Today, racers can choose from dozens of compounds to match their car, category, and driving style. The brake pad is no longer just a wear item—it’s a precision tool. And in modern motorsport, the right pad can make all the difference between late braking… and early retirement.

Brands like CIRCO and Winmax have found fans in Aussie paddocks, offering racing compounds with consistent bite and fade resistance—even on older platforms like APRA Pulsars or RX8 Cup cars or heavily modified Time Attack builds.

And don’t forget just because your car came with something “good enough” doesn’t mean it’s race-ready. Brake upgrades are often the first serious mod racers make—and for good reason.

From Manual to Masterful: Brake Boosting Tech

Once upon a time, your leg did all the work. But now, braking is a brain game too. Modern road and race cars use a combination of:

Hydraulic boosters

Pedal box assemblies

Electric brake-by-wire systems

ABS tuning for grip optimisation

Brake balance adjusters in-cabin for race trim

These aren’t just creature comforts—they help fine-tune how weight is transferred during braking, which, for racers, is the key to better corner entry and lower lap times.

From Stopping to Winning

Brakes aren’t just for slowing down—they’re for going faster. Better brakes let you push deeper into corners, brake later, and stay in control when it counts.

So next time you're on the grid, give a little nod to the humble brake. From wooden blocks to space-age composites, they’ve come a long way—just like your lap times.

MSB Garage | Australia’s motorsport brake specialists – CIRCO Racing Brake Pads, Winmax Brakes, Frenkit and more. Online parts finder at msbgarage.com